Inventory management is a well-studied application, but Advanata takes a uniquely customer-focused approach rather than a traditional operations-research one. This allows customers to easily configure and solve their inventory challenges in a way that aligns directly with how their business actually works.

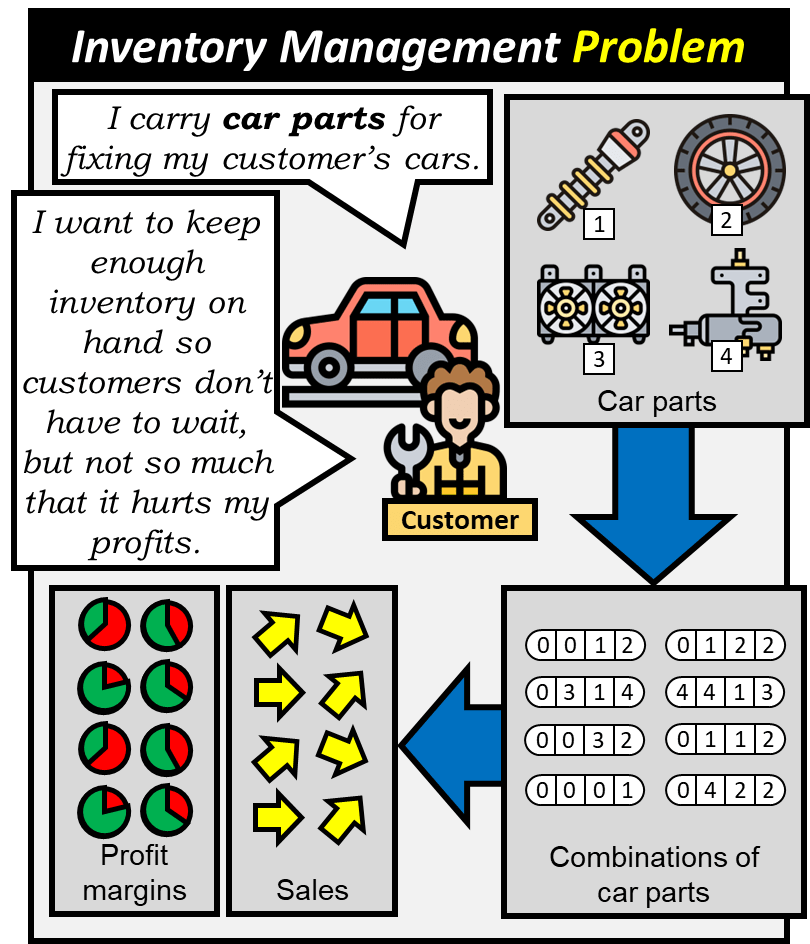

Inventory Management Problem

A garage has to manage its parts inventory. They are not big enough to justify an operations research team, but they are busy enough that inventory management matters. They want short customer lead times, reasonable inventory levels, and strong profitability.

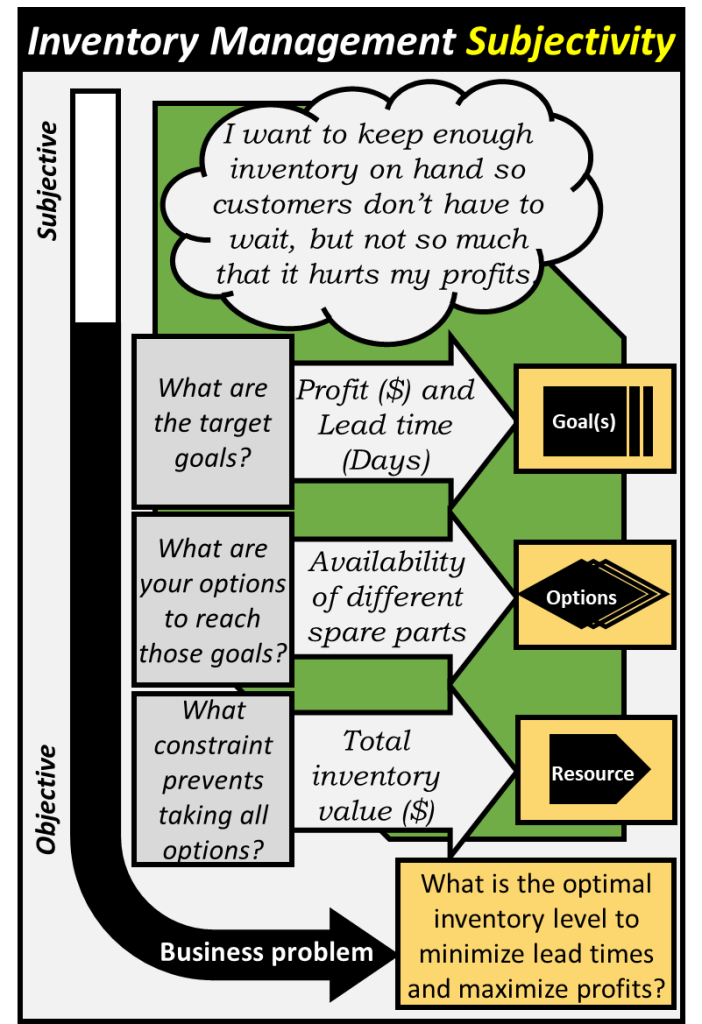

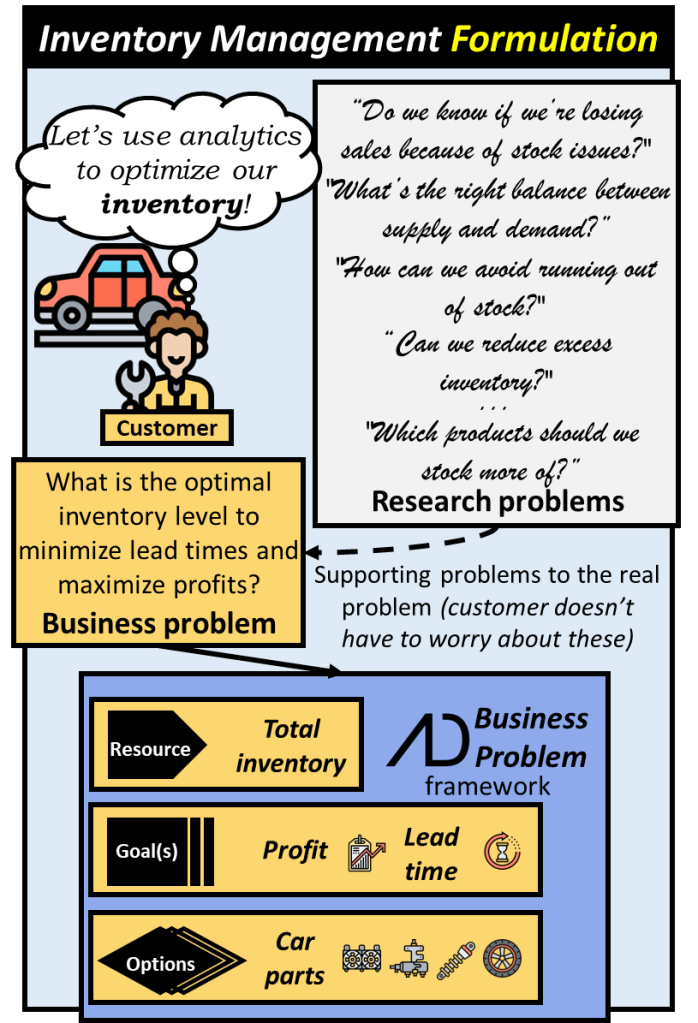

Inventory Management Preparation

Vague customer goals can be easily turned into precise parameters that can be entered into Advanata.

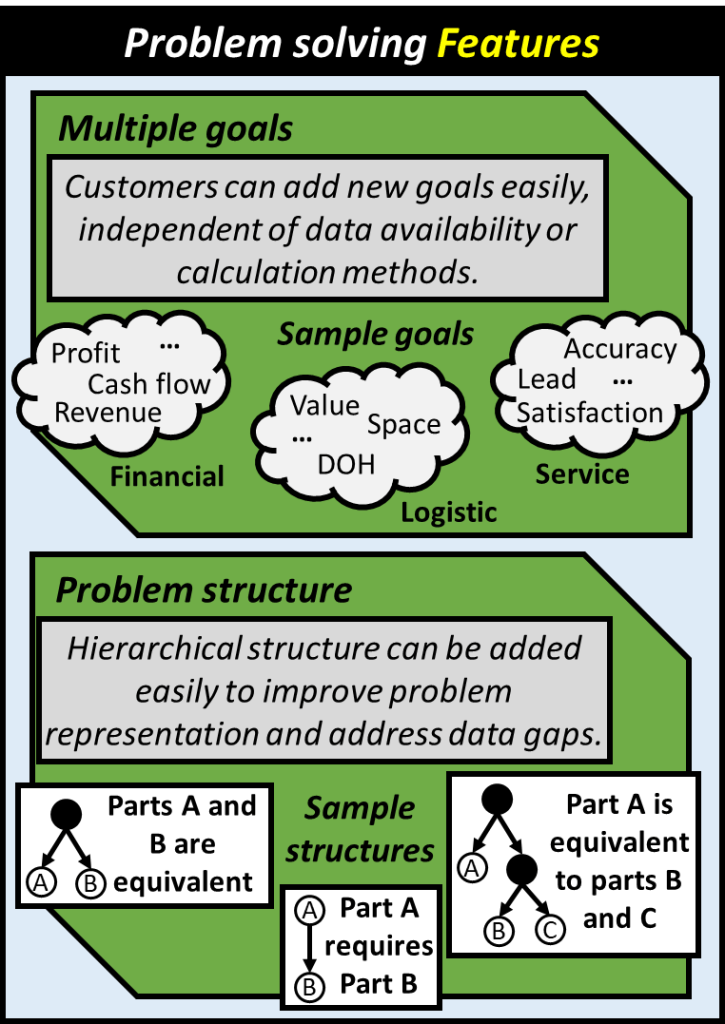

The customer should stay focused on their goals rather than the details of how those goals will be achieved.

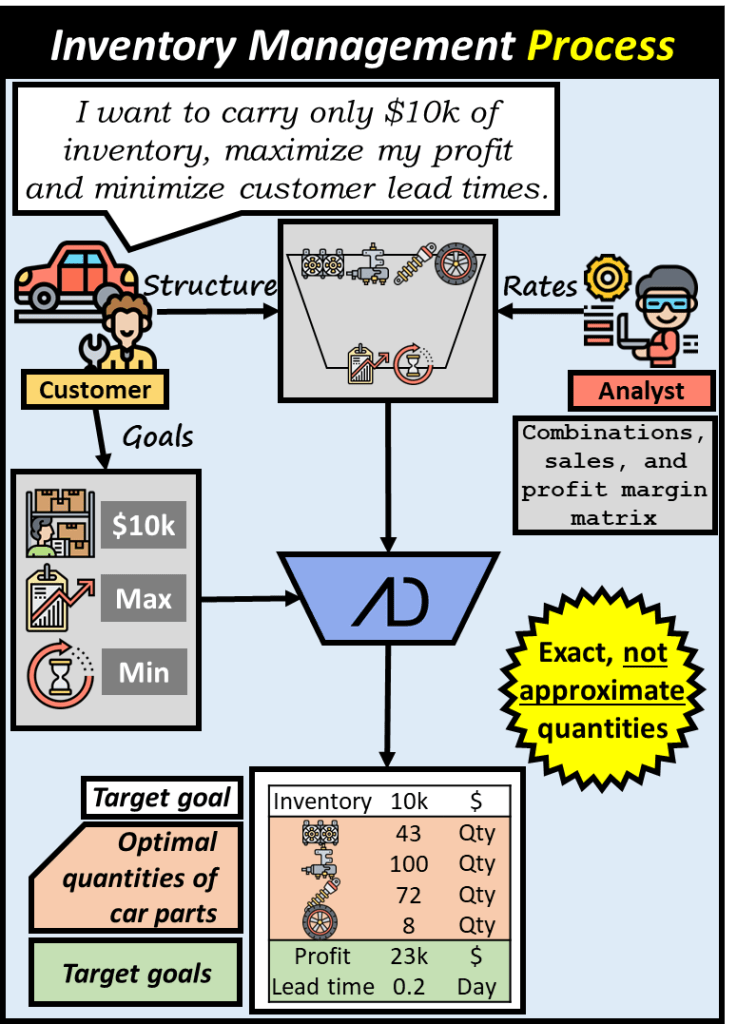

Inventory Management Process

This problem is easy to configure and requires little customer effort. The analyst will handle rate estimation, and alternative sources for rates can be used as needed.

The real strength of Advanata is how easily customers can enhance their inventory management problem by adding new goals or structure without worrying about how the problem will be solved.

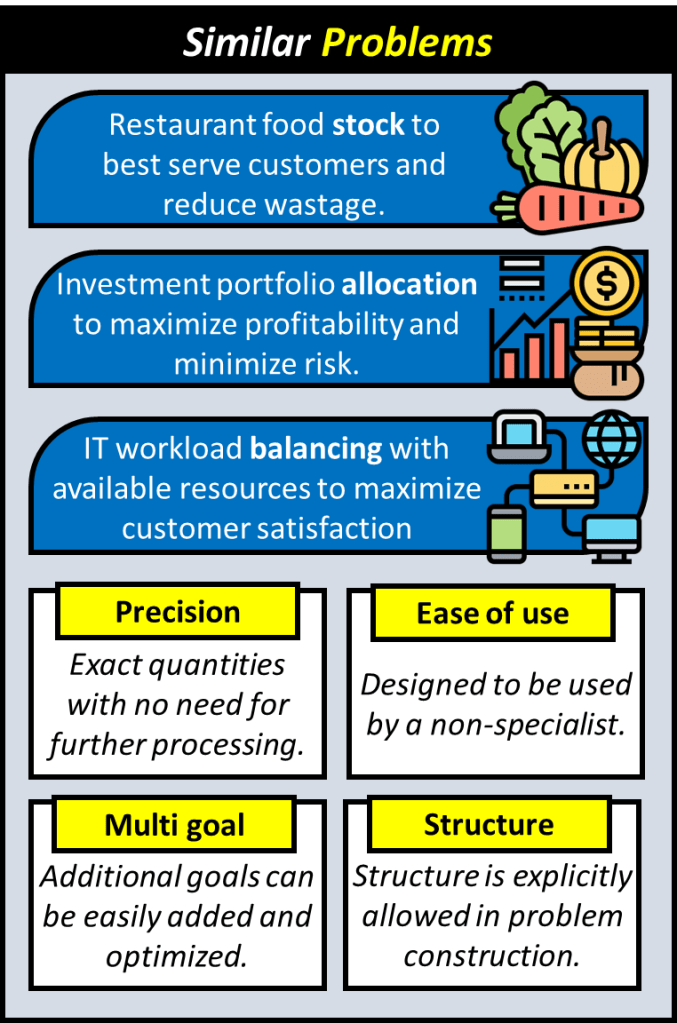

Similar Problems

This approach can solve a surprising range of problems, reflecting the depth of research in inventory management and its influence on business operations across all sectors.

Solving Unique Problems

This is one of the simplest uses of Advanata, yet it applies to a wide range of problems. Most real-world challenges come down to allocating resources to the right actions to achieve the best outcomes, which mirrors the structure of an inventory management problem. With its customer-driven architecture, Advanata allows businesses to apply these methods to improve their operations easily and effectively.

Sign up to get the latest articles and product updates.

Ready to see Advanata in action? Explore more resources, read related articles, and access the full application at advanata.com.

Want a personalized walkthrough? Contact info@advanata.com to get application access and schedule a demo.

Leave a comment